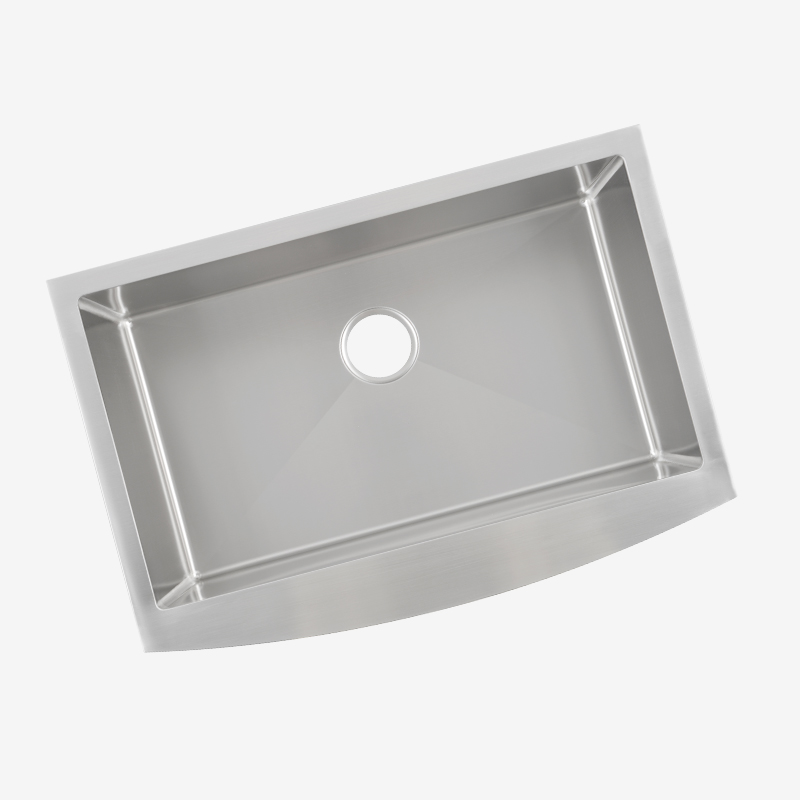

16 gauge SUS304 handmade kitchen sink

Custom Stainless Steel Kitchen Sink In China

- Low MOQ and free samples

- OEM/ODM service or branding with Matrix

- In-House Manufacturing for both handmade sink and pressed sink

- 8.5 years of experience exporting to European and AU markets

85 team members, operating 2 workshops equipped with specialized production lines for both handmade and pressed sinks.

Matrix offers both OEM services and distributes products under the Matrix brand, catering to diverse client preferences.

Matrix accommodates varying order sizes with flexible MOQ and offers free sample services to help customers to test markets and balance risks.

Explore Our Full Range of Stainless Steel Kitchen Sinks

From handmade to pressed sinks, from compact to oversized, Matrix sinks come in a range of sizes, finishes, and mounting types Whether it is a small or large order, we will make sure your needs meet all of our standards with custom-designed options for any budget!

BY Manufacturing Type

Handmade sinks and pressed (or drawn) sinks differ primarily in their manufacturing processes, material thickness, design flexibility, and maintenance requirements.

- Handmade Sinks: Crafted by skilled artisans, these sinks are manually cut, bent, and welded from stainless steel sheets. This meticulous process allows for precise detailing and customization.

- Pressed Sinks: Produced by mechanically stamping thin stainless steel sheets into molds, resulting in uniform shapes suitable for mass production.

- Custom Dimensions & Steel Thicknes

- Tighter Corners, More Room

- Small MOQ, No Tooling Cost

- Completely customizable

- Small Batch trial order

- Thermal conductivity: 0.01234W/(m·K)

- Low Temperature Bending: 0.4564

- Elongation at Break: 0.2645%

- Firmness: 0.454

- Operating Temperature: 1000°C

BY Installation Type

Stainless steel sinks offer three installation options to suit various kitchen cabinets and preferences:

Undermount: The sink is mounted beneath the countertop, creating a seamless appearance and allowing for easy countertop cleaning. This method requires a solid surface countertop, such as granite or quartz, to support the sink’s weight.

Top-Mount (Drop-In): The sink is inserted into a pre-cut hole in the countertop, with the rim resting on the surface. This installation type is compatible with most countertop materials and is generally easier and more cost-effective to install.

Apron Front (Farmhouse): Featuring an exposed front panel that extends past the edge of the cabinetry, apron front sinks offer a distinctive, traditional look. They can be installed as under-mount or top-mount, depending on design preferences and countertop compatibility.

Explore More Kitchen Sink Styles

Our top-mount kitchen sink collection features a full range of styles — including handmade sinks with sharp corners and pressed sinks with soft curves.

Choose from a variety of materials, finishes, and configurations to suit different project types, from single-family homes to large-scale builds.

Looking for a specific size or color? We support full customization.

Trusted Manufacturer of Custom Kitchen Sink

Matrix Industry Co., Ltd. is a premium manufacturer specializing in high-grade stainless steel kitchen sinks, with a robust operational framework and extensive market experience

In-House Manufacturing: Operating 2 production workshops for handmade sinks and pressed sinks, Matrix utilizes specialized production lines to efficiently produce both handmade and pressed sinks, ensuring stringent quality control.

Export Experience: With over 8 years of experience exporting to European and Middle Eastern markets, Matrix has maintained an impeccable record, with no major after-sales issues or product recalls reported to date.

OEM/Branding Services: Matrix offers both OEM services and distributes products under the Matrix brand, catering to diverse client preferences.

Competitive Pricing: Through efficient production processes and strategic supplier relationships, Matrix offers pricing that provides clients with a cost advantage.

Flexible in MOQ and Sampling: Matrix accommodates varying order sizes with flexible MOQ and offers free sample services to meet client needs.

Fully Customizable

OEM Or banding with Matrix

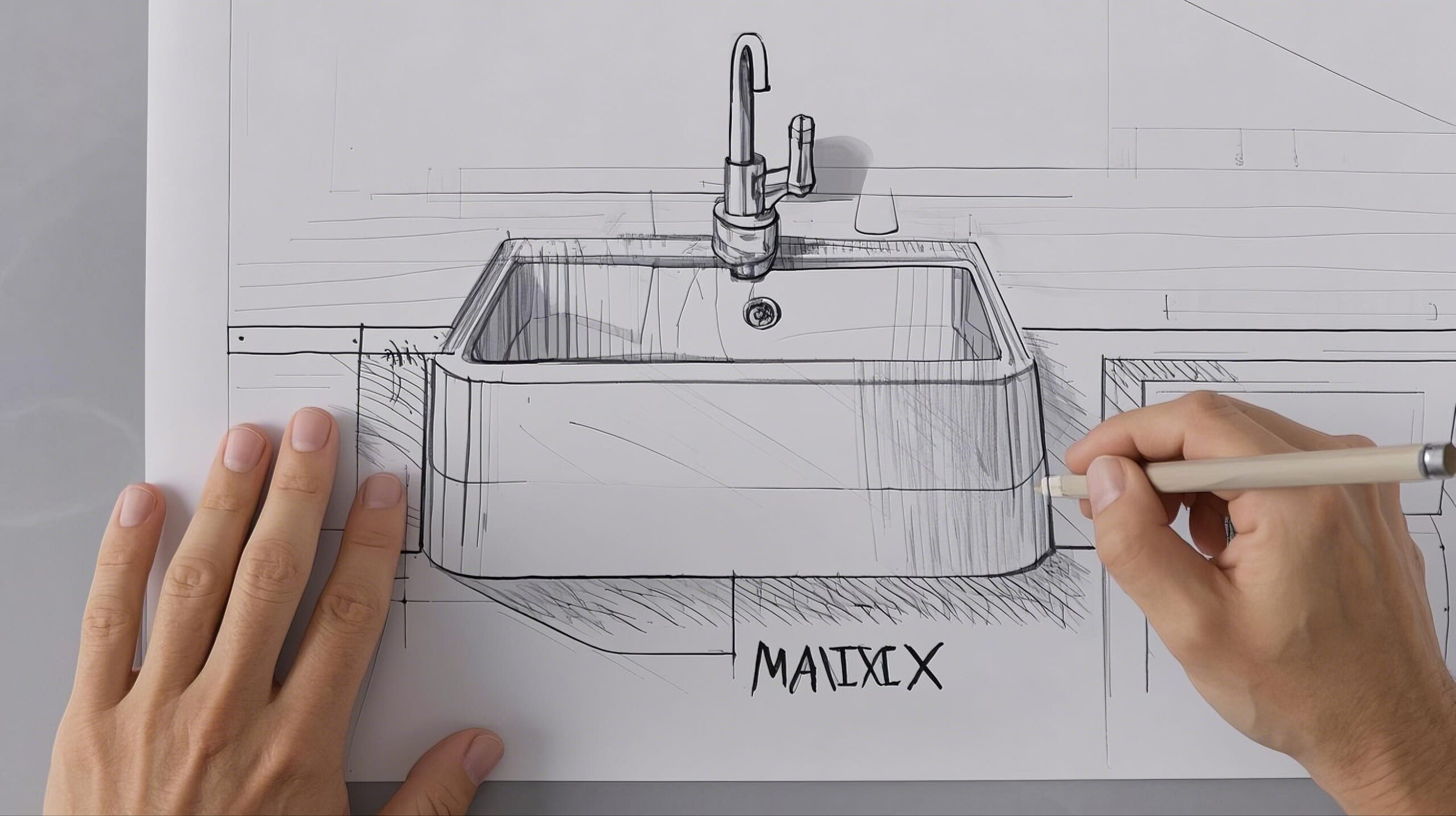

Matrix® offers full OEM & ODM support for stainless steel kitchen sinks — with flexible solutions for brands, developers, and kitchen specialists. From concept to production, we help turn your ideas into market-ready products.

Our 85-person team includes 3 in-house designers and structural engineers. With 2 dedicated workshops for handmade and pressed sinks, we provide 7-day sampling, trial orders from 10 units, and steady production to support your business with confidence.

- 2 workshops supporting both handmade and pressed sinks, adaptable to custom sizes and finishes.

- 2 Complete Manufacturing Production Line

- In-house PD team with 3 engineers and product designers for structural consultation

- Flexible in MOQ, even 10pcs for trial order to test the market

- Standard samples delivered in as fast as 7 working days.

From A new ideal To real kitchen sink

Precision Laser Cutting

High-grade stainless steel sheets are precisely cut using laser technology to match custom sink dimensions, ensuring minimal material waste and consistent accuracy.

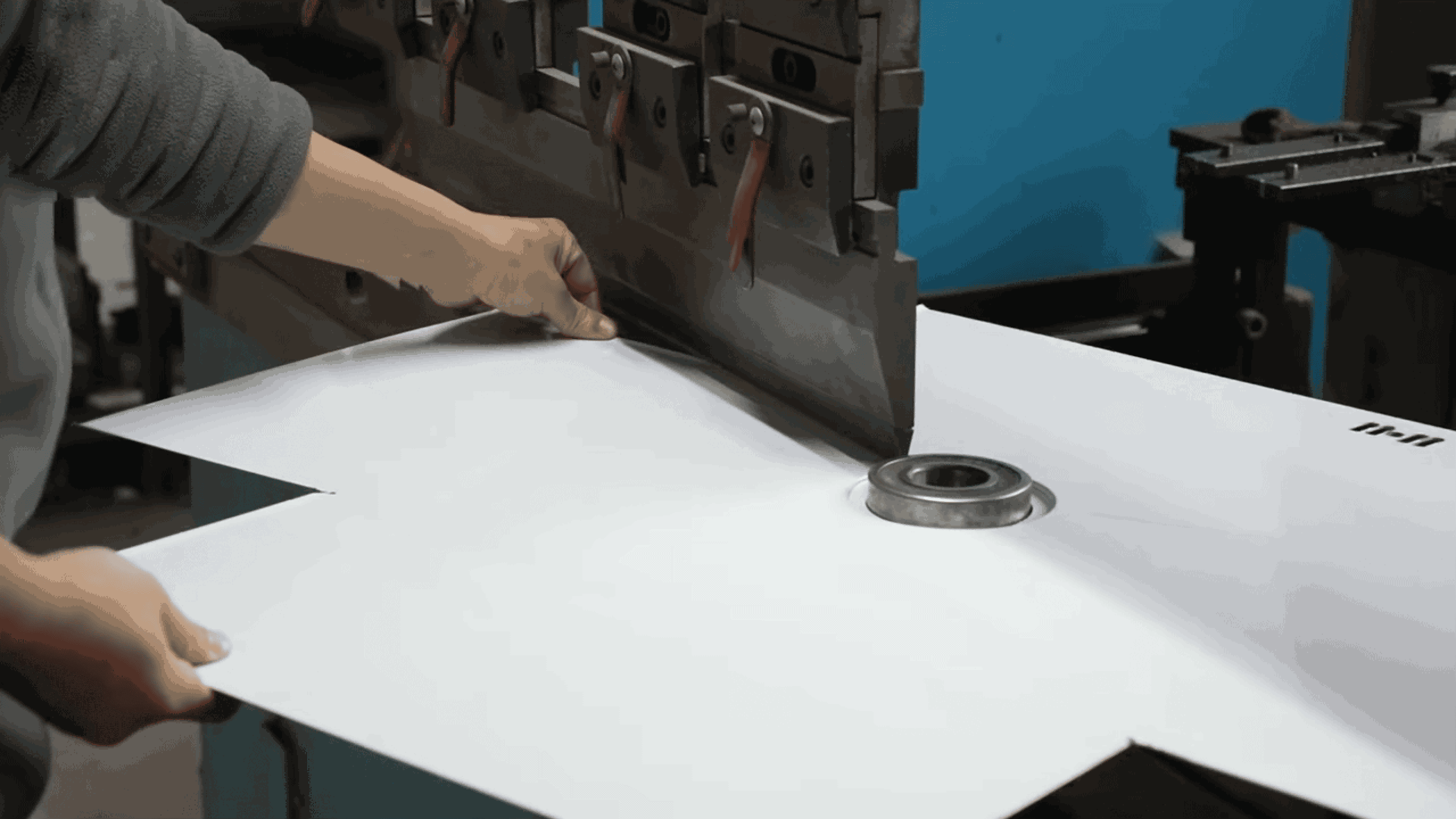

Edge Bending

The stamped sheet is then bent into its final sink shape, preparing it for bowl assembly and welding. This step defines the overall form and depth.

Manual Polishing

Corners (R-angles) and surfaces are carefully polished by hand to enhance the finish, improve touch comfort, and eliminate sharp edges or imperfections.

Structural Stamping

Each cut sheet undergoes mechanical stamping to create drainage lines and edge profiles, forming the functional foundation of the sink.

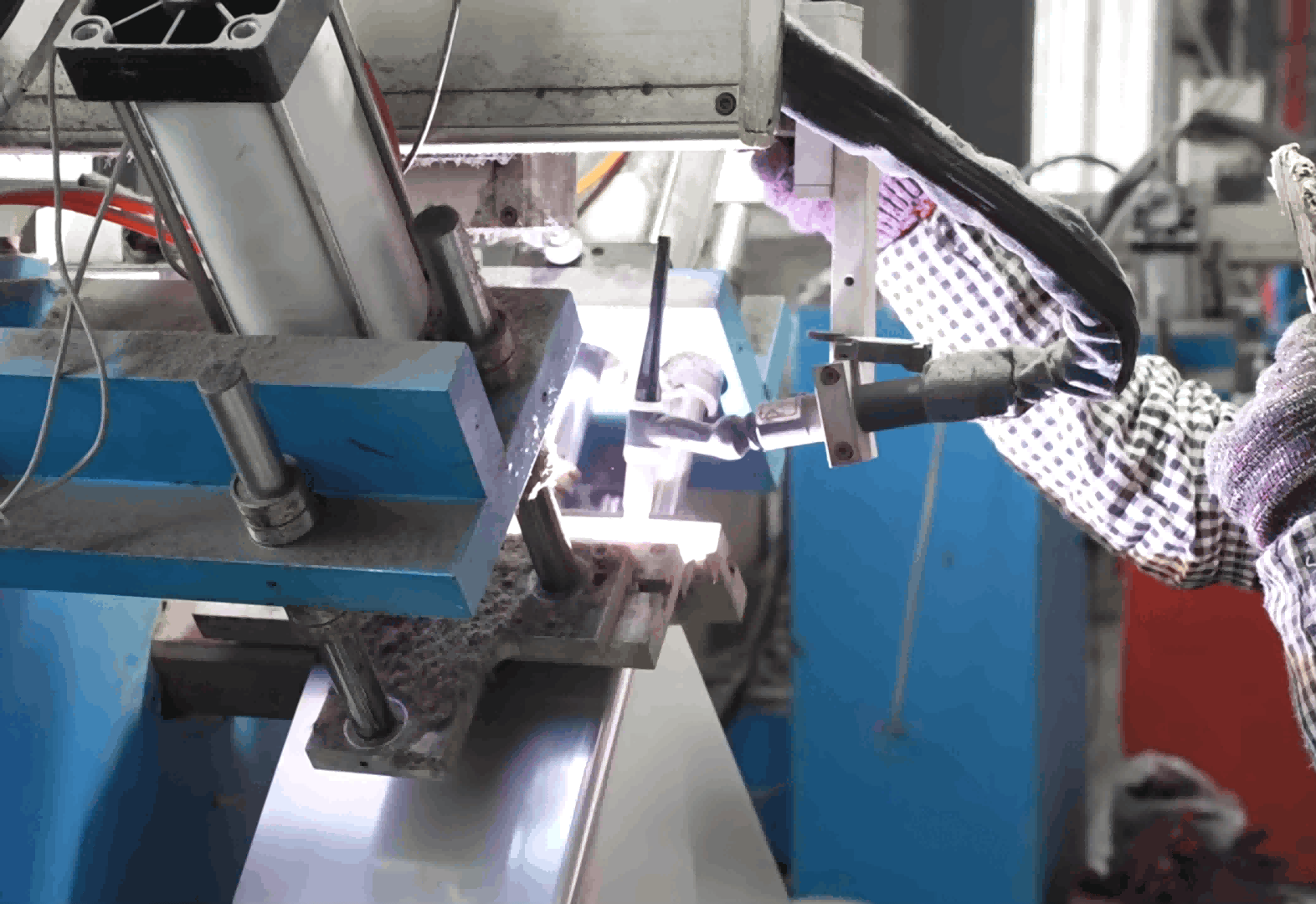

Seamless Welding

Skilled welding—both machine-assisted and hand-finished—joins sink components together. Every weld is checked for strength, durability, and visual consistency.

Surface Treatment

Final treatments are applied to achieve a smooth, stain-resistant finish—available in Nano gold, Nano rose gold, Nano black, , satin or other custom textures—bringing both form and function into balance.

Discover the Right sink for Every application

Matrix® custom under-mount sinks provide a sleek, seamless design that complements any environment — from modern home kitchens to high-demand commercial spaces. With flexible sizing, finish options, and installation compatibility, they fit perfectly into residential, laboratory, hospitality, school canteen, and food service projects.

Laboratory

medical workstation

school canteen

Commercial kitchen

Luxury yacht

Outdoor kitchen

2 Years experiences in working with Menards and Lowe's (LED product)

Tenly Liang, one of the co-founders of Matrix®, balances business and degree. A student of computer science and English, dedicates his weekdays to work and reserves weekends for his studies.

With six years of experience in the industry and close collaboration with U.S. retailers-Menards and Lowe’s, Tenly has learned that trust is built not by pushing and asking, but by listening and providing value.

Common Questions

Most Popular Questions.

Matrix has been exporting stainless steel kitchen sinks to EU and AU markets for 8.5 years, and we have encountered all kinds of problems. Here are the most important concerns of our customers before closing the deal.

Matrix is a premium stainless steel kitchen sink manufacturer, specializing in the design, product development, and manufacturing of high-end kitchen sinks, we have our own manufacturing factory.

Yes, we offer OEM service for all our customers based on their requirements. Moreover, branding with our brand: Matrix.

Yes, we provide free samples for regular sinks.

MOQ might be only charged on the pressed sink, flexible MOQ on the handmade sink.

Pressed sinks are mass-produced using molds, offering uniformity and cost-effectiveness, but charge MOQ. Handmade sinks are crafted individually, allowing for customized designs, style and thickness.

Undermount sinks provide a seamless countertop appearance and easier cleaning, while topmount sinks are simpler to install and replace.

That’s a valuable question.

3 steps to select the right sink:

1. Measure the size of your cabinet which withstands the sink.

2. Check the application and confirm the requirements, like material and surface treatment, some special environments might need very thick material and special coating.

3. Choose your preferred installation method and sink style.

For small orders, generally less than US$200, you can pay through PayPal. But for bulk orders, we could accept 30% T/T advance and 70% T/T before shipment.